OpenSprinkler › Forums › Hardware Questions › OpenSprinkler › Fuse Protection Issue, Burned Triac

- This topic has 14 replies, 5 voices, and was last updated 5 months, 4 weeks ago by

JimS.

-

AuthorPosts

-

August 1, 2022 at 1:34 pm #73536

John KParticipantI just had one of my newest units burn out a zone, I believe the part is called a Triac that burns out, I’ve had this happen before. The solenoid valve tied to that zone still works when powered directly to a 24v power supply. I would like some help sorting out why the damage to the controller happened despite several fuses being used.

From my understanding, the 24V power supply feeds through a 2A fuse before feeding into the system, its built into the controller. I believe the Triac is rated for 800mA (please correct me if I am wrong). I use a 24V power supply that is rated to output up to 1660mA.

For one of the 2 wires from the power supply to the controller (right before orange block), I installed a 1.5A inline fuse, in hopes of extra protection.

The wire I use has 6 zones and a common, typical 18/7 irrigation wire. I used an inline fuse rated at 1A on the common wire, which is of course after the solenoid, heading back the controller. I have 50-60 zones on this controller, so maybe 10 different fused common wires in this manner, which all tie by together post fuse and then head into the controller. My thinking is if one of the solenoids short, it would blow the fuse and the 6 zones tied to that common wire would no longer work until the fuse is fixed. No damage to the controller and I would just need to replace the one bad solenoid then all would work again.

Where have I gone wrong in this thinking? I believe the inline fuse after the solenoid is not ideal, I should place one for each zone right after the controller port and before the solenoid….is that it? Or should this still work?

Is the fuse rated to high? Should I be using 800mA fuses inline to each zone or group of (tied to one common wire)? Would that protect the Triac from burning? Also, the 1.5A fuse after the power supply shouldn’t be an issue if there is a 2A fuse inside the controller anyway…right?

OR

Is this a situation where the Triac burned out for another reason not related to shorting and fuse placements….if so how to I sort this out?My goal with the fuses is to prevent any damage to the controller and still allow me to run 3-6 stations at a time.

August 1, 2022 at 6:32 pm #73539

RayKeymasterTo start, is this an OpenSprinkler or OpenSprinkler Pi? They have slightly different designs regarding where the fuse is placed etc.

August 1, 2022 at 6:46 pm #73541

John KParticipantSorry left out a few details. The unit is the newest one, OS3.2 AC. The burn out occurred on the first extension board, not the controller itself but I assume it works out the same regardless if its on the main controller or on an extension.

August 1, 2022 at 8:04 pm #73542

RayKeymasterYes, the fuse is connected inline with the COM wire so all solenoids will go through the fuse since all are connected to the COM wire. I can’t explain the burn out. The circuit already has a number of protections in place: each zone has a RC snubber circuit to absorb sudden voltage/current changes, it’s protected by a TVS diode for transient high voltage, and there is an inline fuse on the COM wire. The fuse rating should be higher than 800mA because all triacs can sustain a quite high impulse current (up to several amps) in the event of transient high current. Generally, in the event of shorting, a very high amount of current would flow through the fuse, hopefully burning it out to protect the circuit. So exactly how the traic is burned, I don’t know. Is the expander completely unusable or is it that just the first zone is not?

August 2, 2022 at 5:09 pm #73546

John KParticipantHey Ray,

Thank you for the information. Would there be a benefit to to moving the inline fuse to before the solenoid and/or changing to a lower rated fuse for each solenoid? I add them for extra protection and if I have them placed wrong I would like to fix that regardless of this situation, this is where my limited knowledge shows 🙂

The expander works except for the one zone, I’ve sent these in for repair before, looked it over the burn out seems minor, enough to stop working but not a lot of physical damage as I have seen in the past.

August 3, 2022 at 10:19 am #73552

RayKeymasterHave a fuse for each zone would take up a lot of space. I don’t know if you’ve seen the existing fuse, it’s big. The current enclosure has no space for such fuse per zone. But you can certainly add per-zone fuse yourself.

October 12, 2023 at 7:52 pm #77242

JonInAzParticipantI had a similar issue (the burned triac part) with my shiny new v3 OpenSprinkler. Installed, set it up, created a test program to sequence through the stations as a quick test. First two stations (numbering in order of test program, not zone #s) worked fine, the third station never started. Went back inside to the controller, and was met by an acrid smell and a blank display. Unplugged it, noticed transformer was quite warm.

Opened the case and the culprit was obvious – zone 2 triac (which was the third station in the test program).

All of the solenoids connected to the corresponding COM wire (two boxes, two COM wires) show as open. I’d say I also melted the COM wire, but (a) the fuse on the board seems to be intact (it measured about 1 Ohm), and (b) AC supply is rated at 1A. How is possible to blow the triac without blowing the fuse?

I’ll be running new wires to the valves, but I’m trying to puzzle through what actually happened to be sure I address the root cause. As I understand it, the fuse is on the COM ports, and since the current is sensed relative to DC ground, this effectively makes COM the hot AC line, and the switched port of the triac will tie the individual solenoid wire to board ground through the sense resistor. Is this correct?

I should also note: my purchase of the new Opensprinkler was triggered by the demise of the OsPi we’d been using for the last five or six years. I don’t know really when it died – maybe a week prior to the order. When my wife pointed out that the plants were dying I realized the OsPi was dead and being misled by some troubleshooting errors I ordered the new one (the WiFi performance with the OsPi was abysmal so connection was never a sure thing – while the v3 was alive it was much better!)

When I let the smoke out of the new one, I opened up the case of the defunct OsPi. And found the Zone 2 triac toasted there also. But in this case, the fuse had blown.

October 13, 2023 at 10:13 pm #77248

RayKeymasterThe fuse in OpenSprinkler is rated 3A, so it’s possible that the amount of current was enough to burn the triac but not enough to burn the fuse. It’s always tricky to pick the fuse with the right rating — because we always have customers who want to run multiple zones at the same time, if we choose the fuse too low, it will falsely trigger; on the other hand, if it’s too high, it obviously won’t be able to protect anything. We’ve also seen cases where the power adapter’s internal fuse blew before OpenSprinkler’s fuse had a chance to blow. So in reality, it’s not possible to have one fuse rating that fits all situations. If you know roughly what target fuse rating you need you can replace the fuse yourself. It uses the most common type of fuse (5mmx20mm).

Given the symptoms of both your OSPi and OpenSprinkler, you should definitely perform a solenoid resistance testing. You may have a shorted solenoid or shorted wiring somewhere.

October 16, 2023 at 10:19 pm #77265

larryglzParticipantI’ve experienced a very similar problem – a solenoid fails short and overdrives the 24VAC transformer to the extent that in one case it fried the triac and in 2 cases it killed the 24VAC 1000ma transformer. Is there a way for a current limiter, say 500ma, be applied via software to the zones?

October 18, 2023 at 10:18 pm #77277

RayKeymasterI don’t think any software based protection will be able to shut off the triac in time. The short will happen instantly and there won’t be time for the microcontoller to respond. I’ve seen some commercial sprinkler controllers using a huge 10 ohm resistor for short protection. It works, but it’s not going to allow users to open multiple valves at the same time. So in case you don’t open more than 2 valves at a time, you can put a 10 ohm, 25 watt resistor in line with the common wire to server as short protection.

October 21, 2023 at 9:31 am #77306

JonInAzParticipant40 years ago early in my career I got to design both my radio circuits and my test equipment circuits. The standard for the test equipment power was a crowbar circuit- basically a zener is used to trip a triac to short the circuit, blowing the fuse. This works for overvoltage (and most references describe this), but if you put the trigger upstream of a resistor inline with the load, you can set it to trip due overcurrent – the incremental voltage drop across that inline load sets the overcurrent limit.

These were all DC circuits. So for the OS with 24VAC, it would probably need to trigger the crowbar off the current-measurement rectifier.

I am considering inline fuses for the solenoids. Ideally I’d have one 0.3-0.5A fuse per solenoid, and a 1-2A fuse per com line. The former fuses protect the individual triacs, and the latter allow a multiple fault situation (solenoids operating in parallel) to not (usually) blow the onboard fuse, and thereby allow the control to continue to operate.

With the above, if no current flow (or the wrong current flow) is detected when a triac is closed, it means either no solenoid is connected or one of the fuses is blown. This means a simple diagnostic program could be run (as I was running to test my installation). If it shows no current flow when a zone is switched on, you know that either a wire is disconnected or the zone fuse is blown. Furthermore, the OS could log the lack of current during the program.

Ideally these could be placed in a closed fuse block I’d mount adjacent to the OS. I’m not finding one online for 5×20 glass fuses, although they are common for the blade fuses. Unfortunately, the blade fuses are only available down to 1A ratings (and only in the full-size blade package), so the margin gets a lot lower. Blade fuses are designed for DC automotive application but they are rated for 24V DC busses, which means they are actually rated to 32V. I’d want to test, but in a clean environment I think they’d be okay with the ~ 37V peak that might be across a blown fuse in a 24Vac nominal system.

For the glass fuses it looks like I’ll need to either create a bundle of inline fuse holders or mount some PCB sockets to protoboard and put it in a case. Once I put it on a circuit board, I might as well add a couple of LED indicators to each circuit – one is parallel to the fuse, the other goes from the switched port to COM. The latter will illuminate if the board fuse and triac are okay when the zone is switched on, the former will illuminate if the fuse is blown due to a short.

October 21, 2023 at 10:50 pm #77315

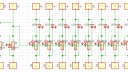

JonInAzParticipantAttached is a notional schematic. The LEDs are shown without resistors; this is simply because I may purchase panel-mount devices with internal current regulators, possibly bipolar.

LEDs 1-8 are red, indicating the corresponding fuse (1-8) is blown or missing.

LEDs 11-18 are green, indicating that the corresponding zone (1-8, in order) is active.

LEDs 19,20 are red or yellow, indicating the corresponding fuse (9 or 10, for zone Com1 or Com2 respectively is blown. (Yes, these could be merged, and probably should be LEDs 9 and 10 anyway.)Fuses F1-F8 are 1A (ideally, about 0.5A), one for each solenoid.

Fuses F9, F10 are 2A (or as appropriate for your load configuration – the idea is that these would blow before the board fuse blows.I’m going to give this a try with blade fuses; I found a block with 0.250″ tab terminals. I can crimp the indicators into the tab terminals; I’ll just need a mounting strip for panel-mount snap-in indicators, and relatively bright indicators if the ones I find are not bipolar.

Attachments:

October 24, 2023 at 8:43 am #77334

larryglzParticipant“I don’t think any software based protection will be able to shut off the triac in time. The short will happen instantly and there won’t be time for the microcontoller to respond. I’ve seen some commercial sprinkler controllers using a huge 10 ohm resistor for short protection. It works, but it’s not going to allow users to open multiple valves at the same time. So in case you don’t open more than 2 valves at a time, you can put a 10 ohm, 25 watt resistor in line with the common wire to server as short protection.”

Thanks Ray. Unfortunately, i do have a use-case where i do run at least 2 valves at the same time. in the mean time, i’m in the process of rigging a smart switch (Shelly) to be triggered “off” in the event the current draw exceeds 800mA. to your point, this is much slower than the event of the short happening, but at least it doesn’t leave the transformer/controller energized when it does detect high current draw.October 30, 2023 at 5:47 am #77372

JimSParticipantI have an OSPi (1.43+). I realize the OP has different hardware but I think most of this would apply. Had an issue with storm transients and some misconnection of an expander board that fried the on board regulator (if I recall correctly – it’s been a LONG time). I elected to remove the damaged regulator and feed the board with an independent 5V regulator so I could feed 12V through the unused ethernet conductors from a supply at the router using a UPS to avoid SD card corruption for short power drops. Not to get too long winded but that’s some back story. I added an in line fuse holder to the 24VAC input- ugly but it works and the fuse is easily replaced. I did build and bench test a solid state AC current limiter that is very simple – just a couple common transistors, some diodes and resistors. My plan was to install it in place of the fuse or possibly in addition to it. Since the fuse only powers the zones now I could easily put this in place of the fuse and only limit current to the zone circuits. Even thought of sensing the current limit and reporting it somehow. I didn’t have further issues so never put the circuit in place but should dig out the details and post it I suppose. My zone expanders have 2.2 ohm resistors in series with the triacs IIRC which just burn up in the case of a short. They burn the PCB making it hard to repair.

October 30, 2023 at 10:53 am #77373

JimSParticipant10 ohm 25W resistor isn’t really adequate protection for shorts. In short situation the current will be 2.4A and power will be 58W (if the supply transformer can supply that much current). It can probably survive the overpower but will be REALLY hot. The supply transformer may be damaged from overload and the heat may damage things. Better to put in some sort of electronic current limit at a convenient level for a couple valves energized at the same time. If you have a system needing a very large number of zones at the same a more complex system would be needed but that’s an uncommon situation.

-

AuthorPosts

- You must be logged in to reply to this topic.

OpenSprinkler › Forums › Hardware Questions › OpenSprinkler › Fuse Protection Issue, Burned Triac